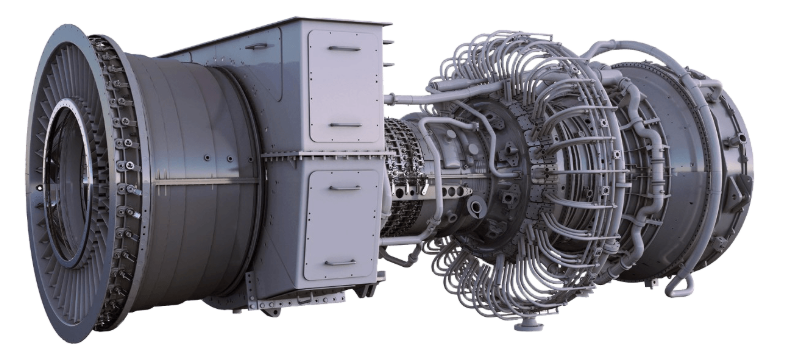

Gas turbines are vital in producing electricity and powering industrial processes. One of the most popular models is the LM6000, known for its efficiency and reliability. However, the smooth operation of this turbine depends heavily on the quality and maintenance of its components. In this article, we will explore how LM6000 parts ensure your gas turbine runs efficiently and safely.

The Importance of High-Quality LM6000 Parts

Every gas turbine has many critical components, and the LM6000 is no exception. LM6000 parts are designed to withstand high temperatures, pressure, and constant mechanical stress. Using original and high-quality parts reduces the risk of unexpected failures, minimizes downtime, and ensures consistent performance. Replacing worn-out components with reliable LM6000 parts helps protect your turbine investment and improves its overall lifespan.

Turbine Blades and Their Role

One of the most essential LM6000 parts is the turbine blades. These blades operate in extreme heat and high-speed airflow. If the blades are damaged or worn, efficiency drops, and the turbine may overheat. Regular inspection and replacement of turbine blades keep the gas turbine operating smoothly. Properly maintained blades ensure optimal energy output and reduce fuel consumption, which is crucial for cost-effective power generation.

Combustion System Components

The combustion system is where fuel is burned to generate the high-pressure gas that drives the turbine. LM6000 parts in the combustion system, such as fuel nozzles and liners, play a crucial role in controlling the combustion process. High-quality parts ensure complete fuel combustion, reduce emissions, and prevent hot spots that could damage other components. Regular maintenance of these parts ensures the turbine runs efficiently while meeting environmental regulations.

Bearings and Shaft Components

Bearings and shafts are the backbone of a gas turbine’s mechanical system. LM6000 parts in these areas ensure smooth rotation of the turbine shaft. Worn bearings can lead to vibrations, noise, and even serious mechanical failure. By replacing bearings and shaft components with genuine LM6000 parts, operators can maintain smooth operation and extend the service life of the turbine. Proper lubrication and monitoring also help prevent unnecessary wear.

Air and Gas Path Components

Air filters, seals, and ducts are critical LM6000 parts that maintain proper airflow within the turbine. Clean and efficient air movement is necessary for optimal combustion and turbine performance. Damaged or clogged components can reduce efficiency and increase maintenance costs. Regular inspection and replacement of these parts ensure that the gas turbine maintains the correct airflow, which is essential for smooth operation.

Monitoring and Control Systems

Modern LM6000 turbines include advanced monitoring and control systems. These systems rely on sensors and other components to track temperature, pressure, and turbine speed. High-quality LM6000 parts in the control system help operators detect potential issues before they become serious problems. Maintaining these components ensures reliable performance, reduces the risk of downtime, and supports safe operation of the gas turbine.

The Benefits of Regular Maintenance

Regular maintenance using genuine LM6000 parts is essential for keeping the turbine running smoothly. Maintenance schedules should include inspection, cleaning, and replacement of critical components. By following manufacturer guidelines and using high-quality parts, operators can prevent unexpected failures, improve efficiency, and reduce long-term costs. Proper maintenance also helps in achieving consistent power output, which is vital for industrial and utility applications.

Conclusion

LM6000 parts play a vital role in ensuring that your gas turbine operates efficiently and reliably. From turbine blades to combustion components, bearings, and control systems, each part contributes to smooth and safe performance. Investing in high-quality parts and adhering to a regular maintenance schedule will help protect your turbine, reduce downtime, and extend its lifespan. Ultimately, well-maintained LM6000 parts are the key to keeping your gas turbine running smoothly and efficiently for years to come.